London City Airport has an ongoing development programme (CADP) that seeks to deliver a range of operational and customer improvements to the working of the airport.

The latest enhancement provides both improved levels of operational safety but also facilitates the introduction of additional next-generation aircraft types to the airport’s approved list.

In what is believed to be a first for a major UK Civil Airport (RAF Northolt has had a similar solution in place for a few years) London City Airport has installing what is known as an Engineered Material Arresting System (EMAS) at both ends of it’s runway.

An EMAS system is the equivalent of a gravel trap that will bring an aircraft to a complete stop in a short distance in case of a brake failure or other over-run situation in either landings or aborted take-offs. The solution has been on the market for over 20 years and has seen most installations at airports within the USA but is being used in more locations where there is limited space and water or other obstacles are located at the airport boundary.

Previously LCY had paved Runway End Safety Areas (RESA) that served that same purpose but as larger aircraft are planned to operate from the airport an enhanced solution that fitted in the available space was required.

[It should be noted that in all the years of LCY’s operations there haven’t been any runway over-run incidents but the added safety margin is a prudent insurance policy.]

The prime contract for the works was awarded to blu-3 and makes use of the Runway Safe EMASMAX® system. The works have taken place during the airport’s closure periods due to the need for access to the live runway and it took place over the Winter period of 2022/3.

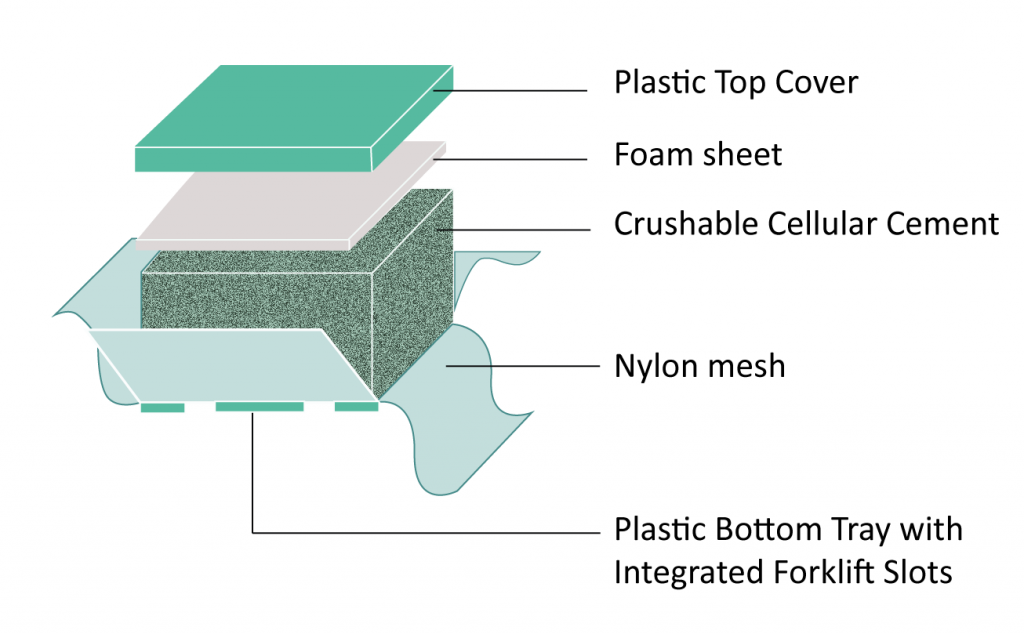

The installation process involved the construction of new areas of asphalt surface on to which stacked layers of the EMAS material sandwich blocks were placed and bonded together. Care also had to be taken to ensure that the runway approach lights were not obstructed by the new surface and access for maintenance works was still possible.

At the Western end of the runway the existing safety zone was extended on to a previously grassed area which required the preparation of a new asphalt surface on to which the EMAS blocks could be installed but that site isn’t easily viewable from public areas so this post focuses on works at the Eastern end of the runway.

The following images show the groundworks to prepare the Eastern runway end area for the installation of the EMAS blocks with similar works happening concurrently at the Western end..

Once all the preparatory works had been completed the laying of the EMAS blocks began – starting with the slopped lead-in section to then create a full EMAS bed the width of the main runway with stepped down sections either side of that.

Further images of the completed installation – note the curved profile of the runway surface and EMAS bed.

The new EMAS solution doesn’t change the operation of the airport with departing aircraft commencing the take-off roll from the same point and landing aircraft fly above the safety area towards the touch-down point.

The blocks are safe to walk on so don’t impede emergency access or passenger egress and are designed to minimize damage to the aircraft thus reducing the operational impact to the airport in the event of an runway excursion.

The following video shows the testing of an EMAS system.

The following images show the Eastern EMAS bed with an aircraft taxing to the departure point and then climbing out.

Update – 2nd May 2023 – I had another look at the Western works zone and managed to capture the following pictures through the window of a moving bus – hence the slightly lower quality of the images!!

Update – 31st May 2023 – the EMAS installations are now complete and a protective outer layer has been applied to both EMAS beds and other project works are undeway.

Update 2nd July 2023

The final element of current runway works project reached a conclusion at the beginning of July with the final changes to the runway markings and the official issue of new aerodrome documentation effective from 13th July 2023.

Alongside the construction of the EMAS beds at both ends of the runway changes have also been made that increases the declared distances available for landing aircraft on both of the runways (slightly different lengths for each – the longer being for Rwy 27).

The extra runway length has been released by the use of the EMAS system within each Runway End Safety Area as less space is now required to bring an aircraft to a safe stop. As a result the thresholds of each runaway along with the touch-down points have been moved closer to the end of the respective runways – thus providing a longer landing area although the physical length of the main landing strip remains the same.

The special 5.5° glide slope remains in use at LCY and the Precision Approach Path Indicators have been moved to correspond with the revised location of the aiming point. The runway approach light configurations have also been revised for the same reason – probably most noticeable on the Rwy 27 approach at the Eastern end of the airport.

The EMAS implementation provides an increased level of operational safety that, combined with the runway layout changes, support the introduction of newer, larger, aircraft such as the Embraer E195 E2.

These new aircraft have a smaller environmental footprint and provide commercial benefits to the operator from having a larger potential seating capacity and/or extended range as well as being more fuel efficient.

Further testing with the E195 E2 is likely to take place in the near future and then see them introduced in to revenue service in coming months.

The following table details the changes to LCY’s declared distances:

| Rwy | TORA | TODA | ASDA | LDA |

|---|---|---|---|---|

| 09 (old) | 1199m | 1319m | 1319m | 1319m |

| 09 (new) | 1199m | 1457m | 1494m | 1494m |

| 27 (old) | 1199m | 1385m | 1319m | 1319m |

| 27 (new) | 1199m | 1415m | 1508m | 1508m |

ASDA = Accelerate-Stop Distance Available / LDA = Landing Distance Available

The first aircraft to land on the “new” Rwy 27 was BA Cityflyer Embraer ERJ-190

G-LCYJ operating the BA8721 flight from Glasgow and landing at LCY at 1236 on Sunday, 2nd July 2023.

A few more of G_LCYJ arriving at LCY following runway layout changes.

There were also a few more circuits undertaken by Diamond DA62 G-GBAS operated by Flight Calibration Services Limited (FCSL) to do some final checks of the lights and navigation aids.

A few more images from the project can be seen by clicking here.